Description

HPL dry facade

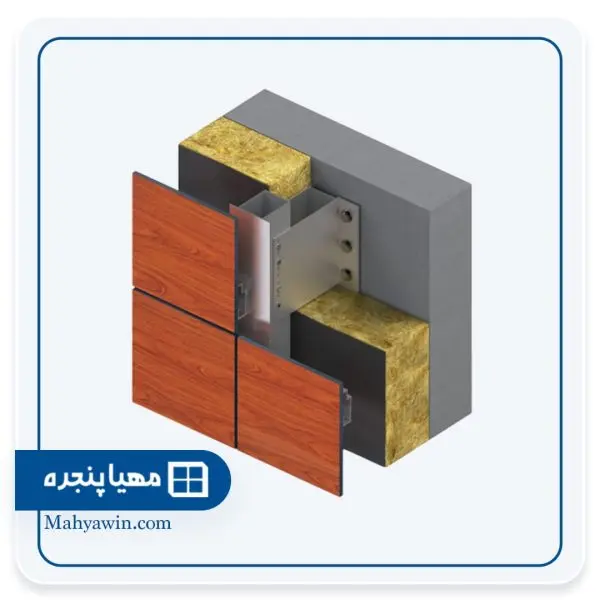

HPL facade is one of the newest building facade materials (dry facade). In this type of view, so-called HPL panels are used.

HPL refers to the plates that are created from the combination of cellulose layers and phenolic resins. After being exposed to a high temperature of 180 c and a pressure of 80 bar, this combination turns into strong plates with special technical specifications.

The final surfaces of these plates are covered by colored layers and anti-scratch coating.

HPL facades are widely used in modern buildings due to their resistance to sunlight, acid rains and moisture and color stability.

Internal and external HPL facade

In addition to the density of the sheet, which shows the quality of HPL, and the flammability, which should be paid attention to when buying the product; Sheet uses are important in choosing the type of product. The final coating of the HPL sheet is decisive in its use cases.

HPLINTERIOR sheet is for internal use, and if it is used externally, it will become pale.

Depending on the location of the HPL facade, different products have been produced. In order to EXTERIOR the INTERIOR sheets and use HPL in the exterior, a layer of melamine or microfilm is used, which is called UV.

But this work does not last much on the exterior and is vulnerable to sunlight and pollution and turns dark over time.

Another EXTERIOR method for HPL is to use the ELECTROBEAM or radiation method, which greatly increases the resistance of the panels and does not darken against sunlight and pollution.

Uses of HPL HPL with various color designs and wood design

Interior and exterior of the building (beautifying the facade of the building with various color designs and wood design, interior and exterior decoration)

Public toilets

Hospitals, laboratories

Decorate the elevator

Making kitchen cabinets

Pool lockers and lockers

And…

The antibacterial, anti-electrostatic and washable properties of HPL (HPL with various color designs and wood designs) provide the cleanliness of the environment, for this reason, the use of HPL plates (HPL with various color designs and wood designs) in restaurants. Hospitals and the interior of the building are also very popular.

HPL facade installation methods

Installation with visible screws:

In this method, the sheets are simply connected to the vertical profiles by screws. 40 x 40 mm cans can be used for underlaying these sheets. The main drawback of this method is the visibility of the used screw.

Installation with hidden screws:

In this method, the screws are covered by caps with the color of the sheet.

Installation by regimental method:

In this method, aluminum profiles are connected to the back of the panel, and as a result, the sheet connection screws are not visible. It seems that this method is more suitable for facade design than other methods.

Among the things that may limit the use of these suitable materials in facade design are some limitations of these sheets on curved surfaces.

It is possible to use HPL sheets in curved facades, but care should be taken in choosing the thickness of the sheet and the installation method.

You can use water and household detergents to clean HPL facades.

How to install HPL with glue

Installation with glue is done in two ways:

A) Installation on aluminum

b) Installation on wood

First, the substrate surface is cleaned with a primer (acetone or thinner if aluminum is used) from any impurity or grease. This can be done using cotton or a clean tissue.

Using a manual stone machine, we remove the coating on the back of the panel to provide more adhesion and friction for the polyurethane glue.

Installation system with visible screws and rivets

HPL facade can be installed using screws or rivets. In this method, panels are connected to vertical columns. If the wall is not fully and vertically aligned (or in other words busy), a mostly iron grid can be used as a second support to adjust the distance of the columns.

40×40 cans are usually used to make the network. Considering that we are facing this problem in Iran, it is recommended to do this.

Reviews

There are no reviews yet.